CAMBRIDGE, Mass. — Copper — the stuff of pennies and tea kettles — is also one of the few metals that can turn carbon dioxide into hydrocarbon fuels with relatively little energy. When fashioned into an electrode and stimulated with voltage, copper acts as a strong catalyst, setting off an electrochemical reaction with carbon dioxide that reduces the greenhouse gas to methane or methanol.

Various researchers around the world have studied copper’s potential as an energy-efficient means of recycling carbon dioxide emissions in powerplants: Instead of being released into the atmosphere, carbon dioxide would be circulated through a copper catalyst and turned into methane — which could then power the rest of the plant. Such a self-energizing system could vastly reduce greenhouse gas emissions from coal-fired and natural-gas-powered plants.

But copper is temperamental: easily oxidized, as when an old penny turns green. As a result, the metal is unstable, which can significantly slow its reaction with carbon dioxide and produce unwanted byproducts such as carbon monoxide and formic acid.

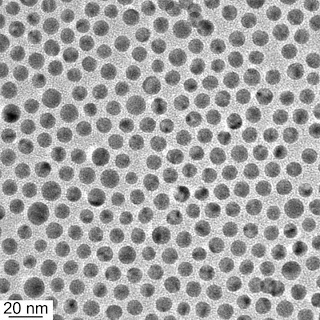

Now researchers at MIT have come up with a solution that may further reduce the energy needed for copper to convert carbon dioxide, while also making the metal much more stable. The group has engineered tiny nanoparticles of copper mixed with gold, which is resistant to corrosion and oxidation. The researchers observed that just a touch of gold makes copper much more stable. In experiments, they coated electrodes with the hybrid nanoparticles and found that much less energy was needed for these engineered nanoparticles to react with carbon dioxide, compared to nanoparticles of pure copper.

Xu then put the nanoparticles through a series of reactions, turning the solution into a powder that was used to coat a small electrode.

To test the nanoparticles’ reactivity, Xu placed the electrode in a beaker of solution and bubbled carbon dioxide into it. He applied a small voltage to the electrode, and measured the resulting current in the solution. The team reasoned that the resulting current would indicate how efficiently the nanoparticles were reacting with the gas: If CO2 molecules were reacting with sites on the electrode — and then releasing to allow other CO2 molecules to react with the same sites — the current would appear as a certain potential was reached, indicating regular “turnover.” If the molecules monopolized sites on the electrode, the reaction would slow down, delaying the appearance of the current at the same potential.

The team ultimately found that the potential applied to reach a steady current was much smaller for hybrid copper-gold nanoparticles than for pure copper and gold — an indication that the amount of energy required to run the reaction was much lower than that required when using nanoparticles made of pure copper.

Going forward, Hamad-Schifferli says she hopes to look more closely at the structure of the gold-copper nanoparticles to find an optimal configuration for converting carbon dioxide. So far, the team has demonstrated the effectiveness of nanoparticles composed of one-third gold and two-thirds copper, as well as two-thirds gold and one-third copper.

Hamad-Schifferli acknowledges that coating industrial-scale electrodes partly with gold can get expensive. However, she says, the energy savings and the reuse potential for such electrodes may balance the initial costs.

“It’s a tradeoff,” Hamad-Schifferli says. “Gold is obviously more expensive than copper. But if it helps you get a product that’s more attractive like methane instead of carbon dioxide, and at a lower energy consumption, then it may be worth it. If you could reuse it over and over again, and the durability is higher because of the gold, that’s a check in the plus column.”

Written by: Jennifer Chu, MIT News Office

Contact: Caroline McCall, MIT Media Relations phone: 617-253-1682 cmccall5@mit.edu WEB: Massachusetts Institute of Technology

1 comment:

nice article. use of nanotechnology is increasing day by day. more research should be continue. I think after some years world will be known as nano world. best wishes to all nanotechnology researchers.

nanoshel.com

Post a Comment