ARLINGTON, Va. -- The development of a new measurement technology under a research project funded by the Air Force Office of Scientific Research and the National Science Foundation is probing the structure of composite and biological materials.

"Our results have provided some of the first microscopic insights into a sixty year old puzzle about the way polymeric networks react to repeated shear strains," said Dr. Daniel Blair, Assistant Professor, and principal investigator of the Soft Matter Group in the Department of Physics at Georgetown University.

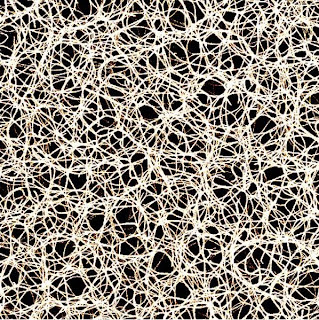

Blair, Professor Andreas Bausch and other researchers at Technische Universtaet Muenchen (Technical University of Munich) used the muscle filament known as actin to construct a unique polymer network. In their quest to understand more about bio-polymers, they developed the rheometer and confocal microscope system (measures the mechanical properties of materials), which provide a unique and unprecedented level of precision and sensitivity for investigating polymeric systems which were previously too small to visualize during mechanical stress experiments. The rheometer and confocal microscopes clearly visualized the fluorescently labeled actin network and they filmed the polymer filaments'movement in 3-D when mechanical stress was applied.

"We will use confocal-rheology as a benchmark system for generating new collaborations and expanding the technique to other AFOSR sponsored projects," said Blair. "For example, in collaboration with Dr. Fritz Vollrath of the Oxford Silk Group and Dr. David Kaplan from Tufts University, we are investigating how shear stress influences the formation of silk fibers."

Blair noted that the new technology is impacting a number of other AFOSR supported projects as a platform for investigating the strengthening of nano-composite networks such as carbon nanotubes and cellulose nanofibers embedded in conventional materials.

Blair predicts that there will be possible private sector uses for the new technology in the area of the green revolution and its inherent smart, soft biological materials.

ABOUT AFOSR:

The Air Force Office of Scientific Research, located in Arlington, Virginia, continues to expand the horizon of scientific knowledge through its leadership and management of the Air Force's basic research program. As a vital component of the Air Force Research Laboratory, AFOSR's mission is to discover, shape, and champion basic science that profoundly impacts the future Air Force.

by Maria Callier Air Force Office of Scientific Research

No comments:

Post a Comment