LOS ALAMOS, N.M., — Certain nanocrystals shown to generate more than one electron after absorbing a single photon.

A team of Los Alamos researchers led by Victor Klimov has shown that carrier multiplication—when a photon creates multiple electrons—is a real phenomenon in tiny semiconductor crystals and not a false observation born of extraneous effects that mimic carrier multiplication.

The research, explained in a recent issue of Accounts of Chemical Research, shows the possibility of solar cells that create more than one unit of energy per photon.

Questions about the ability to increase the energy output of solar cells have prompted Los Alamos National Laboratory researchers to reassess carrier multiplication in extremely small semiconductor particles.

| When a conventional solar cell absorbs a photon of light, it frees an electron to generate an electrical current. Energy in excess of the amount needed to promote an electron into a conducting state is lost as heat to atomic vibrations (phonons) in the material lattice. |

Through carrier multiplication, excess energy can be transferred to another electron instead of the material lattice, freeing it to generate electrical current—thereby yielding a more efficient solar cell.

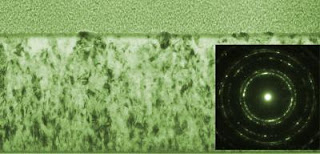

Klimov and colleagues have shown that nanocrystals of certain semiconductor materials can generate more than one electron after absorbing a photon. This is partly due to strengthened interactions between electrons squeezed together within the confines of the nanoscale particles.

In 2004, Los Alamos researchers Richard Schaller and Klimov reported the first observations of strong carrier multiplication in nanosized crystals of lead selenide resulting in up to two electron-hole pairs per absorbed photon. A year later, Arthur Nozik and coworkers at the National Renewable Energy Laboratory reproduced these results. Eventually, spectroscopic signatures of carrier multiplication were observed in nanocrystals of various compositions, including silicon.

Recently, the claims in carrier multiplication research have become contentious. Specifically, some recent studies described low or negligible carrier multiplication efficiencies, which seemed to run contrary to earlier findings. To sort out these discrepancies, Los Alamos researchers analyzed factors that could have led to a spread in the reported carrier multiplication results. These factors included variations between samples, differences in detection techniques, and effects mimicking the signatures of carrier multiplication in spectroscopic measurements.

To analyze how a particular detection technique might affect an outcome, John McGuire, a postdoctoral researcher on Klimov’s team, investigated carrier multiplication using two different spectroscopic techniques—transient absorption and time-resolved photoluminescence. The results obtained by these two methods were in remarkable agreement, indicating that the use of different detection techniques is unlikely to explain discrepancies highlighted by other researchers. Further, although these measurements revealed some sample-to-sample variation in carrier multiplication yields, these variations were much smaller than the spread in reported data.

After ruling out these two potential causes of discrepancies, the researchers focused on effects that could mimic carrier multiplication. One such effect is photoionization of nanocrystals.

“When a nanocrystal absorbs a high-energy photon, an electron can acquire enough energy to escape the material,” Klimov explained. “This leaves behind a charged nanocrystal, which contains a positive ‘hole.’ Photogeneration of another electron by a second photon results in a two-hole, one-electron state, reminiscent of one produced by carrier multiplication, which can lead to false positives,” he said.

To evaluate the influence of photoionization, the Los Alamos researchers conducted back-to-back studies of static and stirred solutions of nanocrystals. Stirring removes charged nanocrystals from the measured region of the sample. Therefore, when crystals are subjected to light, the stirring eliminates the possibility that charged nanocrystals will absorb a second photon. While stirring of some samples did not affect the results of the measurements, other samples showed a significant difference in the apparent carrier multiplication yields measured under static and stirred conditions. Since most previous studies were performed on static samples, these results suggest that discrepancies noted by other researchers arise at least in part from uncontrolled photoionization, which stirring seeks to eliminate.

The Los Alamos researchers re-evaluated carrier multiplication efficiencies when photoionization was suppressed. The results are encouraging.

While the newly measured electron yields are lower than previously reported, the efficiency of carrier multiplication is still greater than in bulk solids. Specifically, both the energetic onset and the energy required to generate an extra electron in nanocrystals are about half of those in bulk solids.

These results indicate significant promise for nanosized crystals as efficient harvesters of solar radiation.

“Researchers still have a lot of work to do,” Klimov cautioned. “One important challenge is to figure out how to design a material in which the energetic cost to create an extra electron can approach the limit defined by a semiconductor band gap. Such a material could raise the fundamental power conversion limit of a solar cell from 31 percent to above 40 percent.”

The Los Alamos nanocrystal team’s research is funded by the U.S. Department of Energy Office of Basic Energy Sciences and Los Alamos’ Laboratory-Directed Research and Development (LDRD) program.

About Los Alamos National Laboratory (www.lanl.gov)

Los Alamos National Laboratory, a multidisciplinary research institution engaged in strategic science on behalf of national security, is operated by Los Alamos National Security, LLC, a team composed of Bechtel National, the University of California, The Babcock & Wilcox Company, and the Washington Division of URS for the Department of Energy's National Nuclear Security Administration.

Los Alamos enhances national security by ensuring the safety and reliability of the U.S. nuclear stockpile, developing technologies to reduce threats from weapons of mass destruction, and solving problems related to energy, environment, infrastructure, health, and global security concerns.

For more information on the research team, visit:

quantumdot.lanl.gov/.

Contact: James E. Rickman

jamesr@lanl.gov 505-665-9203

DOE/Los Alamos National Laboratory