Higher-quality coatings through 'runaway' self-sputtering

BERKELEY, CA – In the electronics industry, thin metal films are deposited on silicon wafers with a sputter gun, which uses energetic ions – atoms with a positive charge – to knock the metal atoms off a target. Scientists at the U.S. Department of Energy's Lawrence Berkeley National Laboratory have now developed a powerful new kind of sputter process that can deposit high-quality metal films in complex, three-dimensional nanoscale patterns at a rate that by one important measure is orders of magnitude greater than typical systems.

Called "self-sputtering far above the runaway threshold," the new method "is an extraordinarily prolific generator of metal ions," says Andre Anders, a senior scientist in Berkeley Lab's Accelerator and Fusion Research Division, where he leads the Plasma Applications Group. Anders and his colleague Joakim Andersson, now at Uppsala University in Sweden, based their new method on the existing technique of High Power Impulse Magnetron Sputtering (HIPIMS).

Berkeley Lab scientists have developed a powerful new kind of sputter process for the electronics industry—and other, more exotic applications, including outer space—which deposits high-quality metal films in complex, three-dimensional nanoscale patterns at a rate that by one important measure is orders of magnitude greater than most existing systems. | Conventional DC (direct-current) sputtering accelerates ions in a plasma – typically a noble gas like argon – to erode atoms from the target. The magnetron design concentrates free electrons near the target in a strong magnetic field, increasing the collision rate between atoms and electrons to create more positive ions that can be accelerated toward the target. HIPIMS, invented in the late 1990s, improves this process further by encouraging self-sputtering, in which some of the metal atoms sputtered off the target are themselves ionized and return to the target to knock off still more atoms. |

The great advantage of HIPIMS is to increase the ratio of metal ions to neutral atoms reaching the substrate, which makes for great improvements in coating quality. Even in HIPIMS, however, the discharge current – in the circuit that powers the sputter gun – is typically more than ten times greater than the current of positive ions that actually reaches the substrate.

But with their new approach, says Anders, "under certain conditions, the ion current can greatly exceed the discharge current." While this sounds counterintuitive, he says, "we don't break any laws of nature, we've just shaken up a few assumptions."

The trick is to send short, very high-power pulses through the magnetron at a low repetition rate. When the voltage is high enough, the ion current does not fall off as the gas is depleted but instead, sustained by self-sputtered metal ions, jumps to a new, much higher level. Self-sputtering continues as long as the power supply can deliver a high-voltage discharge current.

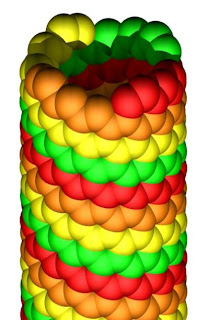

The result: energetic electrons are propelled far from the target and produce a dense plasma of metal ions, even in a vacuum. When the plasma is target metal rather than gas, a higher proportion of metal ions reaches the substrate, insuring that the substrate is coated with a uniform, voidless film with improved properties, such as the ability to penetrate into narrow, nanoscale cavities in intricate semiconductor circuits.

Sustained self-sputtering: how it works

A basic magnetron sputterer is characterized by a strong electric field between the target disk (the cathode) and a grounded anode nearby. The substrate to be coated, which carries a small to moderate negative bias, is positioned at some distance from the target. In the simplest case, a nonreactive gas like argon flows into the chamber and is ionized to create a plasma, a mix of positive ions (atoms missing an electron or two) and free electrons.

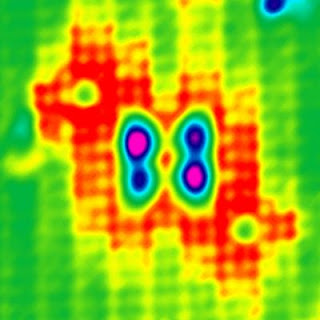

The electric field created by the negative bias of the target disk accelerates positive ions in the plasma, which strike the disk with enough force to liberate (sputter) metal atoms. Most of the acceleration happens in a thin boundary layer called the sheath, a layer where the electric field is concentrated between the target surface and the plasma. The sheath field not only accelerates ions from the plasma toward the target surface but also accelerates electrons away from the target toward the plasma.

Anders calls these accelerated, "hot" electrons "the engines of the discharge." A circular permanent magnet beneath the target creates magnetic field lines that confine most of them close to the target, causing plasma to concentrate in a donut shape on the target and creating a ring-like ion-impact or sputter erosion zone, often labeled the "racetrack".

Self-sputtering, as noted, occurs when target atoms that have themselves been ionized return to the target to knock out yet more target atoms. Some of the sputtered atoms remain neutral and may fly straight to the substrate; others are ionized and may return to the target, producing yet more ions and yet more free electrons (secondary electrons). At low to moderate power levels the ion current reaches a preliminary maximum, and then – as gas temperature increases and sputtered atoms push ionized gas away from the target – the ion current quickly returns to a lower equilibrium.

"To get higher deposition rates and generate more ions, you need to increase the power," says Anders. "But at high power you run the risk of heating the system so much the permanent magnets behind the target demagnetize, or the target starts to melt. So the magnet and cathode assembly have to be water-cooled. And commercial sputter guns the size we use are usually limited to an average power of about a thousand watts, one kilowatt."

"Average power" is an important qualification, says Anders. "If the power is supplied in short pulses, each pulse can exceed the average by up to a hundred times. At that kind of power, all processes become stronger." With the right kind of target material, such as copper, this phenomenon is what makes self-sputtering "far above the runaway threshold" possible.

Once self-sputtering gets started, if enough new atoms get ionized and enough new ions return to the target, it becomes self-sustaining. The magnetic field lines near the target grow thick with spiraling electrons, the plasma is dominated by metal ions instead of gas, and the sheath becomes a potent source of a large flux of energetic electrons that produce still more "excess" plasma – the system runs away, until it finally reaches a new equilibrium at a much higher peak-power level than before.

Achieving equilibrium

"Three quantities determine the self-sputtering threshold," Anders explains. "One is the probability that a sputtered atom gets ionized. Another is the probability that the new ion returns to the target. Finally, there's the actual yield of atoms from self-sputtering. Multiply these together and you get the self-sputtering parameter, which is symbolized by the Greek letter pi" – Π – "When pi equals unity, you reach a new steady state," provided, that is, "that the power supply can keep up."

Which is why, says Anders, "we use a special power supply, up to 500 kilowatts peak power. If the system wants power, we give it power!"

Using a copper target in their HIPIMS system, Andersson and Anders found that the ion current to the collector increased exponentially as the discharge voltage was increased. Far above the threshold of self-sputtering, the ion current to the substrate greatly exceeded the discharge current – a result that came as a surprise to a number of their peers.

"But this really doesn't require any new physics," Anders says. "The ions are generated by the energy invested, not by the current. We provide both high voltage and high current, the product of which is power, so we give the self-sputtering system enough power" – energy per time – "to generate a large amount of ions. It's perfectly compatible with energy conservation or any other law of physics."

In their experiment Andersson and Anders used no process gas at all, but instead kick-started their system with very short arc pulses. Thereafter it operated with a pure plasma of copper formed by means of self-sputtering. They were able to increase the copper-ion current to the substrate right up to the point where the system began arcing too frequently – a discharge mode to be avoided and the practical limit of how far the system could be pushed.

Applications

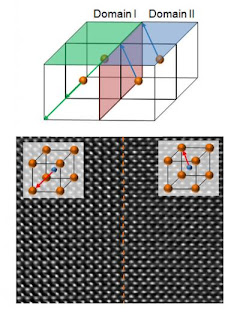

Because intervening gas can affect the deposition of sputtered atoms onto the substrate, especially at high pressure, coatings made with conventional DC sputtering may contain voids that make the coating irregular or even spongy. When the operating plasma is the same species as the target, however – and especially when the atoms that reach the substrate are ionized – voids are not formed. A high proportion of ions also helps deposition reach into the narrowest crevices of the negatively charged substrate.

Beyond the semiconductor industry Anders sees a wide range of applications for the efficient new process, some of which may sound exotic. Because a sustained, self-sputtering plasma can operate in pure vacuum, the new method could also be used for coating materials in space, or even for ion thrusters whose fuel consists of a low-cost, noncombustible metal target, making it unnecessary to carry bottled gases or liquids into space.

Another far-out application may lie in coating the accelerating cavities of the next generation of superconducting particle accelerators with niobium, a metal notoriously difficult to work with. Since every metal behaves differently in a magnetron sputter gun, sustained self-sputtering of niobium is promising but still a challenge.

For now, Andersson and Anders's demonstration of a 250-ampere current of copper ions to a substrate – far higher than any ever achieved in a magnetron system – stands as an achievement with the potential to revolutionize some of the semiconductor industry's most important manufacturing processes. ###

"Self-sputtering far above the runaway threshold: an extraordinary metal ion generator," by Joakim Andersson and Andre Anders, appears in the 30 January 2009 edition of

Physical Review Letters and is available online to subscribers at

link.aps.org/abstract/PRL/.

Berkeley Lab is a U.S. Department of Energy (DOE) national laboratory located in Berkeley, California. It conducts unclassified scientific research and is managed by the University of California for DOE's Office of Science. Visit our website at

www.lbl.gov.

Contact: Paul Preuss

paul_preuss@lbl.gov 510-486-6249

DOE/Lawrence Berkeley National Laboratory