WEST LAFAYETTE, Ind. - Researchers are adapting the same methods used in fusion-energy research to create extremely thin plasma beams for a new class of "nanolithography" required to make future computer chips.

Current technology uses ultraviolet light to create the fine features in computer chips in a process called photolithography, which involves projecting the image of a mask onto a light-sensitive material, then chemically etching the resulting pattern.

New nanolithography will be needed to continue advances in computer technology and to extend Moore's law, an unofficial rule stating that the number of transistors on integrated circuits, or chips, doubles about every 18 months.

The laser method creates plasma by heating xenon, tin or lithium. The plasma produces high-energy packets of light, called photons, of extreme ultraviolet light.

Plasma is a partially ionized gaslike material that conducts electricity. Because of this electrical conductivity, researchers are able to use magnetic fields to shape and control plasmas, forming beams, filaments and other structures. In experimental fusion reactors, magnetic fields are used to keep plasma-based nuclear fuel from touching the metal walls of the containment vessel, enabling the plasma to be heated to the extreme temperatures required to maintain fusion reactions.

HEIGHTS simulates the entire process of the plasma evolution: the laser interacting with the target, and the target evaporating, ionizing and turning into a plasma. The simulation also shows what happens when the magnetic forces "pinch" the plasma cloud into a smaller diameter spot needed to generate the photons.

Findings in the paper detail the laser-produced plasma beams, showing that simulations match data from laboratory experiments recently built at Purdue, Hassanein said.

"It was very exciting to see this match because it means we are on the right track," Hassanein said. "The computer simulations tell us how to optimize the entire system and where to go next with the experiments to verify that."

One design challenge stems from the fact that lenses absorb the photons that make up light, meaning they cannot be used to focus the beam. Instead, mirrors are used in the design. However, plasma condenses on the mirrors, reducing their reflectivity and limiting the efficiency of the process.

"We are trying to help find innovative ways of producing these photons, optimizing the production and mitigating the effects of the plasma on the mirrors," Hassanein said. "So we are trying to improve the entire system."

The simulation tool combines computations in plasma physics, radiation transport, atomic physics, plasma-material interactions and magnetohydrodynamics, or what happens when a target is heated, melts and turns into a plasma. ###

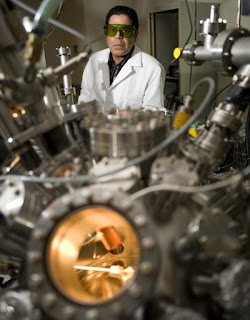

The work is based at the Center for Materials Under Extreme Environments at Purdue. Previous support came from Intel Corp and Sematech, an industry consortium formed to advance computer technology.

Writer: Emil Venere, 765-494-4709, venere@purdue.edu, Source: Ahmed Hassanein, 765 494-5742, hassanein@purdue.edu

Related Web sites:

- Ahmed Hassanein: engineering.purdue.edu/NE/People/

- Center for Materials Under Extreme Environments: engineering.purdue.edu/CMUXE/

No comments:

Post a Comment