UO biologist, neuroscientist Shawn Lockery, shown in his lab, led the development of two microfluidic devices that improve upon older cumbersome tools used to study C. elegans. Photo by Jim Barlow | University of Oregon-led project leads to the creation of two nanotech-driven tools for biologists, neuroscientists.

EUGENE, Ore. -- A pair of new thin, transparent devices, constructed with soft lithography, should boost research in which nematodes are studied to explore brain-behavior connections and to screen new pharmaceuticals for potential treatment of parasitic infections in humans, report 10 scientists at three institutions.

The tools -- an artificial soil device and a waveform sampler device, both of which can be held easily in a human hand -- |

are detailed in a paper appearing online ahead of regular publication by the Journal of Neurophysiology.

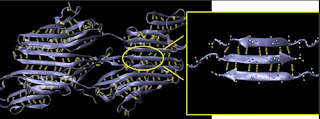

The devices take advantage of a microfluidic fabrication technique, which allows for the presence of channels, chambers or ports, for gas permeability and transparency and for using fluids to deliver stimuli with precision. The major improvement over previous tools is that these new ones are agarose-free, using micron-scale channels and pillars that mimic real soil particles.

The newly reported devices provide a near natural environment for soil-dwelling roundworms (Caenorhabditis elegans, or C. elegans) that measure barely a millimeter in length. The nematodes move normally, but slightly compressed so that highly sensitive microscopes can be used to monitor individual fluorescent-injected neurons in real time during experiments.

"There is a commonality between these devices that is really going to help us understand how the nervous system works," said lead researcher

Shawn Lockery, a professor of

biology and member of the

Institute of Neuroscience at the University of Oregon.

"The artificial soil device consists of a hexagonal array of microscopic pillars sandwiched between a glass cover slip and a bulk material from which the pillars protrude," Lockery said. "The worm wanders around in a one-centimeter square area as a river of mostly water flows through it. We can change the solution the nematode is exposed to in ways that are relevant to the research that is being conducted."

For instance, researchers can manipulate the levels of sodium chloride and oxygen in the water being injected into the devices.

As a proof of principle, researchers had to show that the behavior of the nematodes is essentially normal in the new devices, meaning that the worms crawl like they do on an agar surface. "But nematodes don't live on exposed agar surfaces in real life," Lockery said. Instead, they are found within soil and easily collected in the wild in rotting fruit.

"The beauty of this system is that it reproduces standard laboratory behavior, but it does so in a context that is probably more normal in terms of the worms' real-life environment," he said. "You get forward and reverse locomotion, and the nematodes also do the omega turn, in which a worm's head bends around to touch the tail during forward locomotion, forming a shape like the Greek omega."

The waveform device features 18 different channels, with each divided into domains with unique amplitudes and wavelengths to manipulate how a nematode moves. Instead of using posts to mimic real soil, depressions or channels provide natural areas -- even some that don't occur in nature -- for the nematodes to crawl through. "This ability to change the channels but still allow the worms to move about proved the principle in this case," Lockery said. "What we found from this is that these animals are remarkably adaptable to a wide range of situations."

The artificial soil device, Lockery said, will help to study how brains generally process sensory information and for high-through-put screening of new drugs for their biological effects. Such research, he said, could lead to new treatments for some two billion people infected annually by parasitic nematodes, as well as new tools to reduce nematode-caused losses in world agriculture.

The waveform device could enhance research on brain-behavior connections. C-elegans have only 302 neurons, compared to 100 billion neurons in the human brain, Lockery said. At least 50 percent of the proteins in the nematode brain are identical to those in human brains. "C. elegans is the only animal for which we have a complete anatomical reconstruction of the nervous system -- a complete wiring diagram of the brain. This greatly accelerates analyses of brain function in this organism," he said.

The National Institute of Mental Health and the National Science Foundation funded the research.

In addition to Lockery, four other co-authors of the paper are at the UO. They are Kristy J. Lawton, Serge Faumont, research associates, and postdoctoral researcher Tod R Thiele, all in the UO Institute of Neuroscience, and biology doctoral student Kathryn E McCormick. The other six co-authors are Joseph C. Doll and Sarah Coulthard, mechanical engineering graduate students at Stanford University; Beth L. Pruitt, professor of mechanical engineering at Stanford; Nikolaos Chronis, professor of mechanical engineering and biomedical engineering at the University of Michigan; and Miriam B. Goodman, professor of molecular and cellular physiology at Stanford.

About the University of Oregon: The University of Oregon is a world-class teaching and research institution and Oregon's flagship public university. The UO is a member of the Association of American Universities (AAU), an organization made up of 62 of the leading public and private research institutions in the United States and Canada. Membership in the AAU is by invitation only. The University of Oregon is one of only two AAU members in the Pacific Northwest.

Contact: Jim Barlow

jebarlow@uoregon.edu 541-346-3481

University of Oregon Source: Shawn Lockery, professor of biology, 541-346-4590, shawn@uoregon.edu ###

Tags:

Nano or

Nanotechnology and

Nanotech or

University of Oregon and

nematode or

microfluidic fabrication