Technique creates metal memory and could lead to vanishing dents

CHAMPAIGN, Ill. — Crumpled kitchen foil that lays flat for reuse. Bent bumpers that straighten overnight. Dents in car doors that disappear when heated with a hairdryer. These and other physical feats may become possible with a technique to make memory metals discovered by researchers at the University of Illinois.

Normally, when a piece of metal – such as a paperclip – is bent, the change in shape becomes permanent. But, when heat is added to bent metal films having the right microstructure, the researchers found, the films return to their original shapes. The higher the temperature, the sooner the metal films revert.

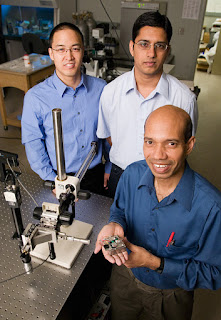

“It’s as though the metal has a memory of where it came from,” said Taher A. Saif, a professor of mechanical science and engineering at Illinois, and senior author of a paper that describes the findings in the March 30 issue of the journal Science.

If the grains are uniformly too small, the metal will be brittle and break while being bent. If the grains are uniformly too large, the metal will bend, but then stay in that position. To return to the initial shape, what’s needed is a balance between brittleness and malleability.

That balance can be achieved through a combination of small and large grains, the researchers report.

Variations in the microstructure lead to plastic deformation in the larger grains and elastic accommodations in the smaller grains, Saif said. The bigger grains bend, but push and pull on the smaller grains, which become elastically deformed like a spring.

If the metal is then left alone, the smaller grains will release this energy and force the bigger grains back to their original shapes over time. This local release of energy can be speeded up by applying heat.

Controlling the crystalline microstructure of thin films also could reduce energy loss in oscillators and resonators used in electronic circuits, Saif said. Oscillators and resonators are found in products ranging from air bag sensors and camcorders to digital projectors and global positioning systems.

“If the grains that constitute the metal films in these devices are between 50 and 100 nanometers, they can be very lossy,” Saif said. “However, if we decrease the grain size, we can reduce much of the energy loss.”

The work was funded by the National Science Foundation.

Editor’s note: To reach Taher Saif, call 217-333-8552; e-mail: saif@uiuc.edu.

Contact: James E. Kloeppel kloeppel@uiuc.edu 217-244-1073 University of Illinois at Urbana-Champaign Released 3/29/07

News Bureau, University of Illinois at Urbana-Champaign, 807 South Wright Street, Suite 520 East, Champaign, Illinois 61820-6261

Telephone 217-333-1085, Fax 217-244-0161, E-mail news@uiuc.edu

Technorati Tags: nanofibers or Nanoscientists and Nano or Nanotechnology and nanoparticles or Nanotech and nanotubes or nanochemistry and nanoscale or nanowires and Nanocantilevers or nanometrology and metal memory or University of Illinois at Urbana-Champaign and microstructure or crystalline microstructure

No comments:

Post a Comment