Sandia’s “Cooler” technology offers fundamental breakthrough in heat transfer for microelectronics, other cooling applications.

Licensing opportunities now available

LIVERMORE, Calif. — Sandia National Laboratories has developed a new technology with the potential to dramatically alter the air-cooling landscape in computing and microelectronics, and lab officials are now seeking licensees in the electronics chip cooling field to license and commercialize the device.

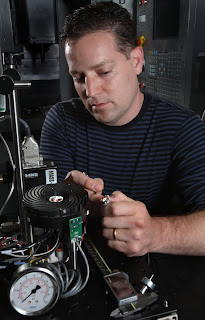

The “Sandia Cooler,” also known as the “Air Bearing Heat Exchanger,” is a novel, proprietary air-cooling invention developed by Sandia researcher Jeff Koplow, who was recently selected by the National Academy of Engineering (NAE) to take part in the NAE’s 17th annual U.S. Frontiers of Engineering symposium.

Koplow said the Sandia Cooler technology, which is patent-pending, will significantly reduce the energy needed to cool the processor chips in data centers and large-scale computing environments. The yearly electricity bill paid by the information technology sector in the U.S. is currently on the order of seven billion dollars and continues to grow.

Companies interested in licensing the Sandia Cooler are invited to review and respond to the solicitation through July 15. The solicitation can be found here. Although it is first focused on licensing opportunities in the field of electronics chip cooling, Sandia will soon establish a separate process for exploring partnering and/or licensing opportunities in other fields.

A technical white paper on the Sandia Cooler technology can be found here.

Sandia’s work on the cooler technology was funded initially through internal investments. Follow-on funding is also being provided by the Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE).

Sandia National Laboratories is a multiprogram laboratory operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration. With main facilities in Albuquerque, N.M., and Livermore, Calif., Sandia has major R&D responsibilities in national security, energy and environmental technologies, and economic competitiveness.

Sandia media relations contact: Mike Janes, mejanes@sandia.gov (925) 294-2447