Moore’s Law, hardly a law but undeniably a persistent trend, says that every year and a half, the number of transistors that fit on a chip roughly doubles. It’s why electronics – from smart phones to flat screens, from MP4 players to movie cameras, from tablets to supercomputers – grow ever more varied, powerful, and compact, but also ever less expensive. Whether the trend can continue until it runs up against immutable laws of nature, like the finite size of an atom, depends on how far scientists and technicians can push electronic technologies down into the nanoworld with better tools for using short-wavelength light.

Now scientists at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have partnered with colleagues at leading semiconductor manufacturers to create the world’s most advanced extreme-ultraviolet (EUV) microscope. Called SHARP (a succinct acronym for a long name, the Semiconductor High-NA Actinic Reticle Review Project), the new microscope will be dedicated to photolithography, the central process in the creation of computer chips.

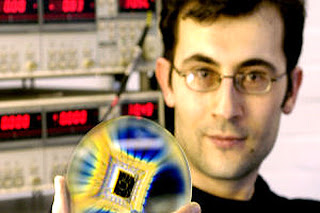

The $4.1 million, 1.5-year project will be led by Kenneth Goldberg of the Center for X-Ray Optics (CXRO) in Berkeley Lab’s Materials Science Division (MSD). Initially SHARP will be used in parallel with operations at the existing microscope on beamline 11.3.2 of Berkeley Lab’s Advanced Light Source (ALS). By the last quarter of 2012 the new EUV photomask-imaging microscope will replace the beamline’s aging facilities.

“EUV light is tricky to work with,” says Goldberg, “because every material absorbs it so strongly. So instead of glass lenses, EUV optical systems rely mainly on specialized mirrors with atomic-scale smoothness, topped by multilayer coatings for high reflectivity.” To maintain efficiency, the entire optical system has to be placed in a high-vacuum environment.

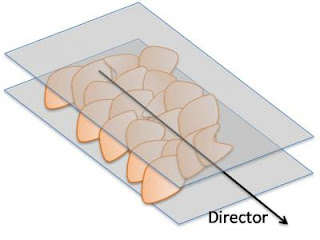

In lithography, photomasks are the key to mass production. A series of photomasks carry the master circuit patterns that are transferred onto a chip, layer by layer, to create working semiconductor devices. The masks are analogous to the negatives in a photographer’s darkroom, or master pages on a photocopier.

Minute imperfections or tiny particles of dust on a master, if not found and cleaned or fixed, ultimately cause chips to fail. Goldberg and his team have shown that defects and patterns can appear very different when viewed with non-EUV inspection tools such as electron microscopes, making EUV microscopy essential for the development of EUV masks because only in this way can damaging dust particles and other defects be identified reliably.

“Other microscopes can have wonderfully high resolution, but they can’t detect the wavelength-specific EUV response of mask patterns and defects,” says Goldberg, “and that’s necessary to make successful repairs.”

SHARP is called an “actinic” microscope because it uses the same EUV wavelengths used in production. Thus the new EUV microscope will enable semiconductor company researchers to better evaluate defects and repair strategies, mask materials and architectures, and advanced pattern features.

Like its predecessor, the SHARP microscope will also feature an array of lenses, side by side, so users can select the different imaging properties they need, much as a common lab microscope mounts different lenses on a rotating turret.

The high-magnification objective lenses for the new microscope are holographic Fresnel zoneplate lenses, microscopic objects produced by CXRO’s Nanowriter. The Nanowriter, under the direction of Erik Anderson, holds the world record for creating the highest resolution zoneplates for many synchrotron and other short-wavelength applications. The lenses are only slightly wider than a single human hair, yet they project high-quality images of the mask surface with up to 2,000 times magnification.

A special feature of the new microscope will be illumination coherence control. The ALS produces an EUV beam with laser-like coherence, ideal for many experiments. For microscopy, however, the image resolution can be improved by a factor of two by carefully re-engineering the illumination into a state called partial coherence. Microscopists have recognized the importance of partial coherence for years, and the synchrotron community is now catching up.

An angle-scanning mirror in the new microscope’s beamline illuminator will take the highly-coherent ALS light and steer it into patterns, like a mini-laser-light show, breaking and re-shaping the coherence properties. In this way, the SHARP microscope will replicate the properties of current and future tools for lithography production and research, giving researchers the most advanced look at what’s to come.

Additional information

With sales of some $51 billion a year, semiconductors are the United States’ second largest export product. Developing technology to produce and test the next generation computer chips is one of the industry’s core missions. For over a decade, semiconductor companies have sponsored photolithography-related research at Berkeley Lab through the Center for X-Ray Optics, including world-leading programs in optics, masks, and materials — most conducted on three CXRO beamlines at the Advanced Light Source.

Contact: Paul Preuss paul_preuss@lbl.gov 510-486-6249 DOE / Lawrence Berkeley National Laboratory

Lawrence Berkeley National Laboratory addresses the world’s most urgent scientific challenges by advancing sustainable energy, protecting human health, creating new materials, and revealing the origin and fate of the universe. Founded in 1931, Berkeley Lab’s scientific expertise has been recognized with 13 Nobel prizes. The University of California manages Berkeley Lab for the U.S. Department of Energy’s Office of Science. For more, visit www.lbl.gov.