A new microspectrometer architecture that uses compact disc-shaped resonators could address the challenges of integrated lab-on-chip sensing systems that now require a large off-chip spectrometer to achieve high resolution.

Spectrometers have conventionally been expensive and bulky bench-top instruments used to detect and identify the molecules inside a sample by shining light on it and measuring different wavelengths of the emitted or absorbed light. Previous efforts toward miniaturizing spectrometers have reduced their size and cost, but these reductions have typically resulted in lower-resolution instruments.

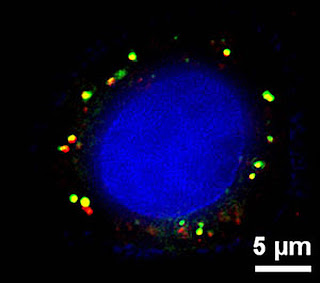

"For spectrometers, it is better to be small and cheap than big and bulky -- provided that the optical performance targets are met," said Ali Adibi, a professor in the School of Electrical and Computer Engineering at the Georgia Institute of Technology. "We were able to achieve high resolution and wide bandwidth with a compact single-mode on-chip spectrometer through the use of an array of microdonut resonators, each with an outer radius of two microns."

The 81-channel on-chip spectrometer designed by Georgia Tech engineers achieved 0.6-nanometer resolution over a spectral range of more than 50 nanometers with a footprint less than one square millimeter. The simple instrument -- with its ultra-small footprint -- can be integrated with other devices, including sensors, optoelectronics, microelectronics and microfluidic channels for use in biological, chemical, medical and pharmaceutical applications.

The microdonut resonators were carefully designed so that each of the resonators only tapped a small portion of the incoming spectrum, thus enabling measurement of the entire spectrum of desired wavelengths in real time.

A key advantage of this microspectrometer design, according to the researchers, is the ability to independently control and configure the resolution and operating bandwidth of each channel for different applications. The device can cover a wide range of wavelengths from approximately one to three micrometers. Extending this concept to the silicon nitride platform also enables spectrometers for visible light applications.

"The microspectrometer we designed may allow individuals to replace the big, bulky, high- resolution spectrometers with a large bandwidth they are currently using with an on-chip spectrometer the size of a penny," noted Adibi. "Our device has the potential to be a high-resolution, lightweight, compact, high-speed and versatile microspectrometer with a large dynamic range that can be used for many applications."

###

Current graduate students Qing Li and Maysamreza Chamanzar also contributed to this work.

This research was supported by the Defense Advanced Research Projects Agency (DARPA) (Award No. HR 0011-10-1-0075) and the Air Force Office of Scientific Research (AFOSR) (Award No. FA9550-06-01-2003). The content is solely the responsibility of the principal investigator and does not necessarily represent the official views of DARPA or AFOSR.

Contact: Abby Robinson abby@innovate.gatech.edu 404-385-3364 Georgia Institute of Technology Research News