When loaded with an anticancer drug, a delivery system based on a novel material called nanosponge is three to five times more effective at reducing tumor growth than direct injection.

That is the conclusion of a paper published in the June 1 issue of the journal Cancer Research.

"Effective targeted drug delivery systems have been a dream for a long time now but it has been largely frustrated by the complex chemistry that is involved," says Eva Harth, assistant professor of chemistry at Vanderbilt, who developed the nanosponge delivery system. "We have taken a significant step toward overcoming these obstacles."

The study was a collaboration between Harth's laboratory and that of Dennis E. Hallahan, a former professor of radiation oncology at Vanderbilt who is now at the Washington University School of Medicine.

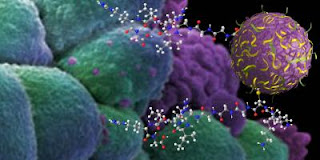

"We call the material nanosponge, but it is really more like a three-dimensional network or scaffold," says Harth. The backbone is a long length of polyester. It is mixed in solution with small molecules called cross-linkers that act like tiny grappling hooks to fasten different parts of the polymer together. The net effect is to form spherically shaped particles filled with cavities where drug molecules can be stored. The polyester is biodegradable, so it breaks down gradually in the body. As it does, it releases the drug it is carrying in a predictable fashion.

"Predictable release is one of the major advantages of this system compared to other nanoparticle delivery systems under development," says Harth. When they reach their target, many other systems unload most of their drug in a rapid and uncontrollable fashion. This is called the burst effect and makes it difficult to determine effective dosage levels.

Another major advantage is that the nanosponge particles are soluble in water. Encapsulating the anti-cancer drug in the nanosponge allows the use of hydrophobic drugs that do not dissolve readily in water. Currently, these drugs must be mixed with another chemical, called an adjuvant reagent, that reduces the efficacy of the drug and can have adverse side-effects.

It is also possible to control the size of nanosponge particles. By varying the proportion of cross-linker to polymer, the nanosponge particles can be made larger or smaller. This is important because research has shown that drug delivery systems work best when they are smaller than 100 nanometers, about the depth of the pits on the surface of a compact disc. The nanosponge particles used in the current study were 50 nanometers in size. "The relationship between particle size and the effectiveness of these drug delivery systems is the subject of active investigation," says Harth.

The other major advantage of Harth's system is the simple chemistry required. The researchers have developed simple, high-yield "click chemistry" methods for making the nanosponge particles and for attaching the linkers, which are made from peptides, relatively small biological molecules built by linking amino acids. "Many other drug delivery systems require complicated chemistry that will be difficult to scale up for commercial production, but we have continually kept this in mind," Harth says.

The targeting peptide used in the animal studies was developed by the Hallahan laboratory, which also tested the system's effectiveness in tumor-bearing mice. The peptide used in the study is one that selectively binds to tumors that have been treated with radiation.

The drug used for the animal studies was paclitaxel (the generic name of the drug Taxol) that is used in cancer chemotherapy. The researchers recorded the response of two different tumor types – slow-growing human breast cancer and fast-acting mouse glioma – to single injections. In both cases they found that it increased the death of cancer cells and delayed tumor growth "in a manner superior to know chemotherapy approaches."

The next step is to perform an experiment with repeated injections to see if the nanosponge system can stop and reverse tumor growth. Harth is also planning to perform the more comprehensive toxicity studies on her nanoparticle delivery system that are required before it can be used in clinical trials. ###

Additional participants in the study were Ralph J. Passarella, Daniel E. Spratt, John G. Phillips, Hongmei Wu and Li Zhou from the Vanderbilt University Medical Center and Alice E. van der Ende and Vasanth Sathiyakumar from Vanderbilt's Department of Chemistry.

The research was supported by grants from the Department of Defense, National Science Foundation and National Institutes of Health.

Contact: David F. Salisbury david.salisbury@vanderbilt.edu 615-343-6803 Vanderbilt University