Award-winning materials expert and UH grad returns with SuperPower, Inc

Although the U.S. electric power industry is one of the greatest engineering marvels of the 20th century, aging technology and an increase in demand create problems for the electricity infrastructure that need to be fixed.

Venkat Selvamanickam, director of the Applied Research Hub and the M.D. Anderson chair professor of the department of mechanical engineering, University of Houston, is developing a technology with high temperature superconducting wires that is revolutionizing the way power is generated, transported and used.

Venkat Selvamanickam (center) surrounded by his team of SuperPower researchers who have joined him at the University of Houston. | "The country's electric transmission grid currently consists of about 160,000 miles of high-voltage transmission lines, with forecasters predicting an additional 12,900 miles needed over the next five years to meet increasing demand," said Selvamanickam. "The goal of my research is to modernize the power grid with high temperature superconducting wires to improve efficiency and reliability. Almost anything in the power grid– cables, transformers, motors, generators – can be more efficient if you use high temperature superconducting wires.

Superconducting power cables can transmit up to 10 times more power than traditional copper cables without the significant losses of traditional cables and are considered environmentally friendly. Superconducting fault current limiters can enable uninterrupted power transmission when conventional circuits will otherwise succumb to outages in events such as lightning storms." |

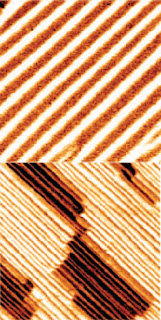

On a tour of Selvamanickam's research laboratory at Texas Center for Superconductivity at the University of Houston, he demonstrates different samples of the high temperature superconducting wire that resemble a shiny, metal tape about the size of a hair ribbon, with similar flexibility. The tape has six to eight layers with a ceramic-middle, one-hundredth as thick as human hair, consisting primarily of a coating made from a mixture of yttrium barium copper oxide, generally called YBCO (pronounced IB-co).

High temperature superconductivity defines certain materials like metals and ceramics that lose electrical resistance when cooled by liquid nitrogen, an inexpensive industrial refrigerant that costs less than a bottle of water, a major development in the price point for superconductivity for wide commercial use.

Without this resistance, electrons can travel through these materials freely, leading to wires fabricated into power cables that carry large amounts of electric current for long periods without losing energy as heat. Cooled by liquid nitrogen, high temperature superconducting wires reduce risk of explosion in that it's not flammable.

The applications for high temperature superconducting wire range from advanced medical imaging techniques like magnetic resonance imaging (MRIs) to large-scale applications replacing existing copper wires with superconducting wires to raise reliability and cut costs in electric power transmission and distribution, storage devices, motors, generators, cellular communication systems, to magnetically-levitated trains.

"High temperature superconductivity has the potential to revolutionize the way we use electricity, just like the way fiber-optics revolutionized the way we communicate," said Selvamanickam. "Our research pays immediate returns to the industry. It's not like something that maybe 10 years down the line could be useful."

It is estimated that high-temperature superconducting wires could eliminate 131 million tons of carbon dioxide released into the atmosphere and offset the emission of the equivalent of 40 conventional electricity-generating plants.

Before joining the University of Houston in 2008, Selvamanickam was the chief technology officer at SuperPower. He received his Ph.D. in materials engineering from UH in 1992 and his master's degree in mechanical engineering in 1988. As a graduate student, he created a new method for fabricating high performance superconductors. One of his publications that arose from his master's thesis on superconductivity became one of the most cited works on the subject setting international standards for superconductor performance. He continued the trend of setting world-record performances in superconductor wire in his industrial career at SuperPower.

"SuperPower is one of a handful of companies to develop and manufacture second-generation high temperature superconducting wires in kilometer-long lengths commercially available around the world today. They produce the world's highest-performance wire," said Selvamanickam.

Based in Schenectady, New York, SuperPower signed a research agreement with the University of Houston and is the first partner in the new applied research hub of the Texas Center for Superconductivity at the University of Houston (TCSUH). The company plans to establish a presence in Houston with a specialty products facility at UH's Energy Research Park. Selvamanickam oversees SuperPower's research and development activities from Houston as a chief technical advisor.

In moving its research to the University of Houston, SuperPower transferred to the University unique, thin-film process equipment to make the wire.

"No other university in the country has this kind of equipment. We also have five SuperPower scientists now working out of Houston who also train and mentor graduate students working on the project," said Selvamanickam.

"One reason the University of Houston was selected for its research agreement was its strong commitment to superconductivity research," said University of Houston President Renu Khator. "The Texas Center for Superconductivity houses the largest university-based multidisciplinary research center in the world and is enthusiastic about working with an industry leader like SuperPower."

SuperPower's achievements include demonstrating the world's first integration of high-temperature superconducting wire installed in the grid in upstate New York as part of the Albany Cable Project, a Department of Energy flagship program. SuperPower and Waukesha Electric Systems along working with the University of Houston and Oak Ridge National Laboratory will be installing a fault limiting superconducting transformer in Southern California Edison utility substation, California's largest grid, in 2015.

Selvamanickam attributes his success in the challenging field of superconductivity to being in the right place at the right time as a graduate student at the University of Houston.

"I was at the birthplace of high temperature superconductivity as a graduate student in 1987 at the University of Houston. At the time, Paul Chu, director of the Texas Center for Superconductivity discovered YBCO that broke the liquid nitrogen barrier for superconducting temperature," said Selvamanickam. "I was one of the first researchers to work on the material Chu discovered. We worked around the clock trying to make the material, perform 100 times better. I came up with a new technique to fabricate superconductors and achieved a world record in January 1989 that's still a standard today."

After receiving his degree, Selvamanickan worked at the Oak Ridge National Laboratory for a year as a post-doctoral researcher, then joined Intermagnetics General Corp. In 1996, President Bill Clinton awarded him the Presidential Early Career Achievement Award. He used the $500,000 received from the award as seed money to develop a ground breaking superconducting wire technology at Intermagnetics which was the foundation for the start of SuperPower in 2000. From 2000 to 2008, he built and managed a team of 40+ high-performance personnel and led the company to multiple word firsts including the completion of the world's first significant delivery of second-generation high temperature superconducting wire and multiple world records for superconductor wire performance.

Selvamanickam was named Superconductor Industry Person of the Year in 2005 and his numerous accomplishments in this field are documented with more than 145 papers in several major journals, 30 issued patents and 21 pending U.S. patents, and more than 60 pending international patents.

After nearly 25 years of working in superconductivity, Selvamanickam still finds it a magical phenomenon and is fueled by passion and drive to be a leader in his field.

"There is no theory to explain why these materials are superconducting," Selvamanickam said. "Another thing that gives me goose bumps is there are materials out there that could be superconducting at room temperature, and we don't know it yet."

Contact: Melissa Carroll

mcarroll@uh.edu 713-743-8153

University of Houston