Adventures in microsolar supported by microelectronics and MEMS techniques.

ALBUQUERQUE, N.M. — Sandia National Laboratories scientists have developed tiny glitter-sized photovoltaic cells that could revolutionize the way solar energy is collected and used.

The tiny cells could turn a person into a walking solar battery charger if they were fastened to flexible substrates molded around unusual shapes, such as clothing.

The solar particles, fabricated of crystalline silicon, hold the potential for a variety of new applications. They are expected eventually to be less expensive and have greater efficiencies than current photovoltaic collectors that are pieced together with 6-inch- square solar wafers.

Another manufacturing convenience is that the cells, because they are only hundreds of micrometers in diameter, can be fabricated from commercial wafers of any size, including today's 300-millimeter (12-inch) diameter wafers and future 450-millimeter (18-inch) wafers. Further, if one cell proves defective in manufacture, the rest still can be harvested, while if a brick-sized unit goes bad, the entire wafer may be unusable. Also, brick-sized units fabricated larger than the conventional 6-inch-by-6-inch cross section to take advantage of larger wafer size would require thicker power lines to harvest the increased power, creating more cost and possibly shading the wafer. That problem does not exist with the small-cell approach and its individualized wiring.

Other unique features are available because the cells are so small. "The shade tolerance of our units to overhead obstructions is better than conventional PV panels," said Nielson, "because portions of our units not in shade will keep sending out electricity where a partially shaded conventional panel may turn off entirely."

Because flexible substrates can be easily fabricated, high-efficiency PV for ubiquitous solar power becomes more feasible, said Okandan.

A commercial move to microscale PV cells would be a dramatic change from conventional silicon PV modules composed of arrays of 6-inch-by-6-inch wafers. However, by bringing in techniques normally used in MEMS, electronics and the light-emitting diode (LED) industries (for additional work involving gallium arsenide instead of silicon), the change to small cells should be relatively straightforward, Gupta said.

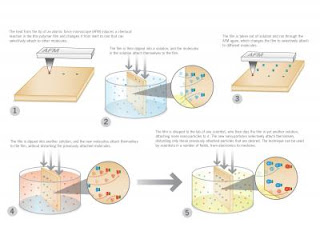

Each cell is formed on silicon wafers, etched and then released inexpensively in hexagonal shapes, with electrical contacts prefabricated on each piece, by borrowing techniques from integrated circuits and MEMS.

Offering a run for their money to conventional large wafers of crystalline silicon, electricity presently can be harvested from the Sandia-created cells with 14.9 percent efficiency. Off-the-shelf commercial modules range from 13 to 20 percent efficient.

A widely used commercial tool called a pick-and-place machine — the current standard for the mass assembly of electronics — can place up to 130,000 pieces of glitter per hour at electrical contact points preestablished on the substrate; the placement takes place at cooler temperatures. The cost is approximately one-tenth of a cent per piece with the number of cells per module determined by the level of optical concentration and the size of the die, likely to be in the 10,000 to 50,000 cell per square meter range. An alternate technology, still at the lab-bench stage, involves self-assembly of the parts at even lower costs.

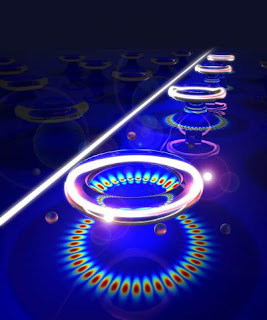

Solar concentrators — low-cost, prefabricated, optically efficient microlens arrays — can be placed directly over each glitter-sized cell to increase the number of photons arriving to be converted via the photovoltaic effect into electrons. The small cell size means that cheaper and more efficient short focal length microlens arrays can be fabricated for this purpose.

High-voltage output is possible directly from the modules because of the large number of cells in the array. This should reduce costs associated with wiring, due to reduced resistive losses at higher voltages.

Other possible applications for the technology include satellites and remote sensing. ###

The project combines expertise from Sandia's Microsystems Center; Photovoltaics and Grid Integration Group; the Materials, Devices, and Energy Technologies Group; and the National Renewable Energy Lab's Concentrating Photovoltaics Group.

Involved in the process, in addition to Nielson, Okandan and Gupta, are Jose Luis Cruz-Campa, Paul Resnick, Tammy Pluym, Peggy Clews, Carlos Sanchez, Bill Sweatt, Tony Lentine, Anton Filatov, Mike Sinclair, Mark Overberg, Jeff Nelson, Jennifer Granata, Craig Carmignani, Rick Kemp, Connie Stewart, Jonathan Wierer,

George Wang, Jerry Simmons, Jason Strauch, Judith Lavin and Mark Wanlass (NREL).

The work is supported by DOE's Solar Energy Technology Program and Sandia's Laboratory Directed Research & Development program, and has been presented at four technical conferences this year.

The ability of light to produce electrons, and thus electricity, has been known for more than a hundred years.

Sandia National Laboratories is a multiprogram laboratory operated by Sandia Corporation, an autonomous Lockheed Martin company, for the U.S. Department of Energy's National Nuclear Security Administration. With main facilities in Albuquerque, N.M., and Livermore, Calif., Sandia has major R&D responsibilities in national security, energy and environmental technologies, and economic competitiveness.

Contact: Neal Singer nsinger@sandia.gov 505-845-7078 DOE/Sandia National Laboratories