Isotopes, the atomic clues used to solve crimes, date ancient artifacts and identify chemicals.

Whether it's the summer grass that tickles your feet or the red Bordeaux smacking on your palette, nearly every part of the world around you carries special chemical markers. These markers, called isotopes, can tell scientists where the molecules that compose a substance are from, where they traveled, and what happened to them along the way. But doing these analyses has been complex and costly. Now, Stanford chemists have developed a new method to make isotopic analysis easier and less expensive.

"It's all done with smoke and mirrors," said chemist Richard Zare, giving a very literal description of the new method. The device he and his collaborators have created burns chemical samples into a gas, which then flows through a laser beam that is bouncing back and forth off a set of mirrors inside a special container.

Richard Zare, Stanford University | The atoms of a particular element all have the same number of protons in their core, but may have differing numbers of neutrons. Carbon, for example, has six protons, but the number of neutrons in carbon atoms can vary from six to seven or eight. Each variation is an isotope of carbon.

Zare had the idea that it could be possible to distinguish different isotopes by the colors of light from the laser that they absorb when the original molecules are converted to smaller molecules through combustion. |

"Think of them as being balls of different color," said Zare the Marguerite Blake Wilbur Professor in Natural Science and chair of the chemistry department. The tool can calculate the ratio of isotopes in a sample by simply "counting the colors and comparing them." This principle also makes the instrument more versatile than current mass spectrometers because Zare's device can analyze isotopes of different elements at the same time without being re-calibrated..

The equipment needed for the new method is smaller, cheaper, lighter and more portable than previous methods, and is easier to use. It has the potential to bring the power of isotopic analysis within easy reach of a host of researchers who have not had access to the expensive equipment that has been needed, Zare said. He and his collaborators report on their method in a paper scheduled to be published Monday, June 29, in the online early edition of the Proceedings of the National Academy of Sciences.

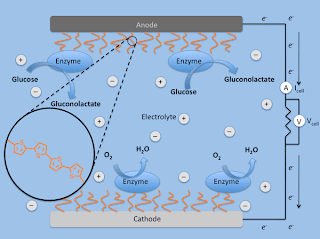

Isotopic analysis is used in a wide range of research, including geochemistry, medicine, and climatology. Until now, the analysis has been done using an isotope ratio mass spectrometer, which works by giving individual molecules an electric charge, then using a magnet to separate the isotopes by their mass—the more neutrons, the more mass. One machine can cost as much as a million dollars. In addition to being expensive and large, mass spectrometers now in use require specially trained technicians to operate them.

Zare's device, which employs what is called cavity ring-down spectroscopy, has potential applications in fields as varied as medicine, geology and winemaking, he said. "Some people are willing to pay a lot of money for wine," Zare said. "You allow me to measure the isotopes, I'll tell you whether you're paying your money for the real thing or not."

Because an element's isotopes are more plentiful in certain places than in others, the ratios of different isotopes within a larger mixture act like travel diaries – they can tell you the history of a mixture, whether it's from a different country, a particular part of the human body, or a previous time period. Determining the history of a mixture by measuring the ratios of its isotopes is known as isotopic analysis.

To illustrate, Zare explained that certain plants, such as corn, contain more carbon-13 than other plants. Because Americans tend to eat more corn than Europeans, isotopic analysis would detect more carbon-13 in the breath exhaled by an American than in the breath exhaled by a European, Zare said.

Doctors and pharmacologists can use isotopic analysis to measure the targeting precision of a specific drug by testing samples of urine and breath to see if the right organs have properly metabolized it. Also, climatologists can learn more about the ancient earth by studying carbon dioxide locked within cores of ice, Zare said.

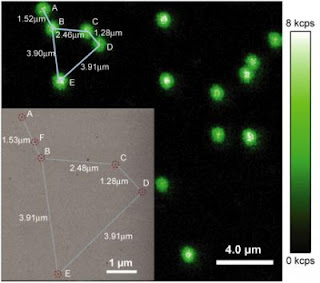

Zare and his students worked together with researchers from Picarro, Inc., a start-up company he helped found, to create a prototype. They have successfully tested its performance by measuring carbon isotopes in different organic compounds such as methane, ethane, and propane. The bulky magnets that are the most expensive components of an isotope mass spectrometer are unnecessary in Zare's device, cutting costs while achieving an acceptable level of performance, according to Zare's team. Another advantage: the device can be used with minimal training.

Existing isotope ratio mass spectrometers can weigh as much as 1500 pounds and occupy the space of a large freezer case, such as those found an ice cream shop

Once the prototype is fully developed and commercialized, "It'll fit into the backseat of a car," Zare said. This portability can take isotopic analysis directly into the field, whether it's a doctor's office or a vineyard.

However, the team does see room for improvement.

The instrument's isotope ratio measurements are currently accurate within one to three parts per thousand, which is sufficient enough for the team to make a case for an alternative to isotope ratio mass spectrometry. However, this is still 10 to 30 times less accurate than isotope ratio mass spectrometers. The team emphasizes that their current results are preliminary and are only used to demonstrate the viability of their technique.

"My goal is to become better than and actually replace isotope ratio mass spectrometry," Zare said. He sees this as a possibility within the next 5 to 10 years. ###

Zare's co-authors on the paper include Stanford chemistry graduate student Douglas Kuramoto and Christa Haase, an undergraduate in chemistry at ETH, the Swiss Federal Institute of Technology, in Zurich, Switzerland, who worked in Zare's lab last summer. A grant from Picarro, Inc., a private gas analyzer manufacturer that Zare serves as a technical advisor and of which he is a founding member, supported the development of the current prototype. Other co-authors of the paper are Sze Tan, Eric Crosson, and Nabil Saad, researchers at Picarro, Inc.

Contact: Dan Stober

dstober@stanford.edu 650-721-6965

Stanford University