STORRS, Conn. - Chemists at the University of Connecticut have found a way to greatly increase the luminescence efficiency of single-walled carbon nanotubes, a discovery that could have significant applications in medical imaging and other areas.

Increasing the luminescence efficiency of carbon nanotubes may someday make it possible for doctors to inject patients with microscopic nanotubes to detect tumors, arterial blockages and other internal problems. Rather than relying on potentially harmful x-rays or the use of radioactive dyes, physicians could simply scan patients with an infrared light that would capture a very sharp resolution of the luminescence of the nanotubes in problem areas.

Fotios Papadimitrakopoulos: SINGLE WALL CARBON NANOTUBES (SWNTs) VIDEO: The wrapping of SWNTs with a seamless, conformal helix made out of small molecular weight material has been a major challenge in the field of SWNTs. | UConn's process of increasing the luminescence efficiency of single-walled carbon nanotubes will be featured in Science magazine on Friday, March 6, 2009. The research was performed in the Nanomaterials Optoelectronics Laboratory at the Institute of Materials Science at the University of Connecticut, in Storrs, CT. A patent for the process is pending. University of Connecticut Chemist Fotios Papadimitrakopoulos describes the discovery as a major breakthrough and one of the most significant discoveries in his 10 years of working with single-walled carbon nanotubes. Assisting Papadimitrakopoulos with the research were Polymer Program graduate student Sang-Yong Ju (now a researcher at Cornell University) and William P. Kopcha, a former Chemistry undergraduate assistant in the College of Liberal Arts and Sciences who is now a first-year graduate student at UConn. |

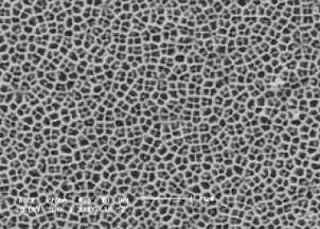

By tightly wrapping a chemical 'sleeve' around a single-walled carbon nanotube, Papadimitrakopoulos and his research team were able to reduce exterior defects caused by chemically absorbed oxygen molecules.

This process can best be explained by imagining sliding a small tube into a slightly larger diameter tube, Papadimitrakopoulos says. In order for this to happen, all deposits or protrusions on the smaller tube have to be removed before the tube is allowed to slip into the slightly larger diameter tube. What is most fascinating with carbon nanotubes however, Papadimitrakopoulos says, is the fact that in this case the larger tube is not as rigid as the first tube (i.e. carbon nanotube) but is rather formed by a chemical "sleeve" comprised of a synthetic derivative of flavin (an analog of vitamin B2) that adsorbs and self organizes onto a conformal tube.

Papadimitrakopoulos claims that this process of self-assembly is unique in that it not only forms a new structure but also actively "cleans" the surface of the underlying nanotube. It is that active cleaning of the nanotube surface that allows the nanotube to achieve luminescence efficiency to as high as 20 percent.

The nanotube is the smallest tube on earth and we have found a sleeve to put over it," Papadimitrakopoulos says. "This is the first time that a nanotube was found to emit with as much as 20 percent luminescence efficiency."

Papadimitrakopoulos has been working closely with the UConn Center for Science and Technology Commercialization (CSTC) in transferring his advances in research into the realm of patents, licenses and corporate partnerships. The CSTC was created several years ago as a way to help expand Connecticut's innovation-based economy and to help create new businesses and jobs around new ideas.

This is the second major nanotube discovery at UConn by Papadimitrakopoulos in the past two years. Last year, Papadimitrakopoulos and Sang-Young Ju, along with other UConn researchers, patented a way to isolate certain carbon nanotubes from others by seamlessly wrapping a form of vitamin B2 around the nanotubes. It was out of that research that Papadimitrakopoulos and Sang-Yong Ju began wrapping nanotubes with helical assemblies and probing their luminescence properties.

The more luminescent the nanotube, the brighter it appears under infrared irradiation or by electrical excitation (such as that provided by a light-emitting diode or LED). A number of important applications may be possible as a result of this research, Papadimitrakopoulos says. Carbon nanotube emissions are not only extremely sharp, but they also appear in a spectral region where minimal absorption or scattering takes place by soft tissue. Moreover, carbon nanotubes display superb photo bleaching stability and are ideally suited for near-infrared emitters, making them appropriate for applications in medicine and homeland security as bio-reporting agents and nano-sized beacons. Carbon nanotube luminescence also has important applications in nano-scaled LEDs and photo detectors, which can readily integrate with silicon-based technology. This provides an enormous repertoire for nanotube use in advanced fiber optics components, infrared light modulators, and biological sensors, where multiple applications are possible due to the nanotube's flavin-based (vitamin B2) helical wrapping. ###

Additional Contact Information: Fotios Papadimitrakopoulos Professor of Chemistry Associate Director, Institute of Materials Science University of Connecticut Tel: (860)-486-3447, Fax: (860)-486-4745, Email: papadim@mail.ims.uconn.edu

More information about the University of Connecticut's Nanomaterials Optoelectronics Laboratory can be found at: chemistry.uconn.edu/papadim/

Contact: Colin Poitras colin.poitras@uconn.edu 860-486-4656 University of Connecticut