Lodamin appears to retain TNP-470's potency and broad spectrum of activity, but with no detectable neurotoxicity and greatly enhanced oral availability. While a number of angiogenesis inhibitors, such as Avastin, are now commercially available, most target only single angiogenic factors, such as VEGF, and they are approved only for a small number of specific cancers. In contrast, Lodamin prevented capillary growth in response to every angiogenic stimulus tested. Moreover, in mouse models, Lodamin reduced liver metastases, a fatal complication of many cancers for which there is no good treatment.

"The success of TNP-470 in Phase I and II clinical trials opened up anti-angiogenesis as an entirely new modality of cancer therapy, along with conventional chemotherapy, radiotherapy and surgical approaches," says Ingber, now co-interim director of the Vascular Biology Program at Children's.

TNP-470 was first reformulated several years ago by Ronit Satchi-Fainaro, PhD, a postdoctoral fellow in Folkman's lab, who attached a large polymer to prevent it from crossing the blood-brain barrier (Cancer Cell, March 2005). That formulation, Caplostatin, has no neurotoxicity and is being developed for clinical trials. However, it must be given intravenously.

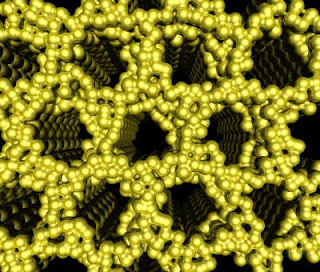

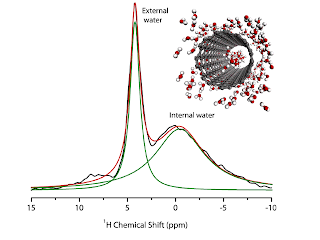

Benny took another approach, attaching two short polymers (PEG and PLA) to TNP-470. Experimenting with polymers of different lengths, she found a combination that formed stable, "pom-pom"-shaped nanoparticles known as polymeric micelles, with TNP-470 at the core. The polymers (both FDA-approved and widely used commercially) protect TNP-470 from the stomach's acidic environment, allowing it to be absorbed intact when taken orally. The micelles reach the tumor, react with water and break down, slowly releasing the drug.

Tested in mice, Lodamin had a significantly increased half-life, selectively accumulated in tumor tissue, blocked angiogenesis, and significantly inhibited primary tumor growth in mouse models of melanoma and lung cancer, with no apparent side effects when used at effective doses. Subsequent tests suggest that Lodamin retains TNP-470's unusually broad spectrum of activity. "I had never expected such a strong effect on these aggressive tumor models," Benny says.

Notably, Lodamin accumulated in the liver without causing toxicity, preventing liver metastases and prolonging survival. "This was one of the most surprising things I saw," says Benny. "When I looked at the livers of the mice, the treated group was almost clean. In the control group you couldn't recognize the livers -- they were a mass of tumors."

TNP-470 itself has an interesting history. It was derived from fumagillin, a mold with strong anti-angiogenic effects that Ingber discovered accidentally while culturing endothelial cells (the cells that line blood vessels). Ingber noticed that in certain dishes -- those contaminated with the mold -- the cells changed their shape by rounding, a behavior that inhibits capillary cell growth. Ingber cultured the fungus, disregarding lab policy, which called for contaminated culture to be discarded immediately. He and Folkman later developed TNP-470, a synthetic analog of fumagillin, with the help of Takeda Chemical Industries in Japan (Nature, December 1990). It has shown activity against dozens of tumor types, though its mechanism of action is only partly known.

"It's been an evolution," says Benny, "from fumagillin to TNP-470 to Caplostatin to Lodamin." ###

Lodamin and Caplostatin have been optioned for clinical development by SynDevRx, Inc., a Cambridge, Mass.-based biotechnology company. Benny, who is from Israel, coined the name Lodamin from Hebrew. ("Lo dam" means "no blood.") She continues to study Lodamin's effects in other animal models of cancer, and in macular degeneration with Robert D'Amato, MD, PhD, in the Vascular Biology program.

Folkman, the Lodamin paper's senior author, died unexpectedly in January, just days after Benny submitted the paper for publication. The paper, a part of his legacy, is dedicated to his memory.

The study was supported in part by the U.S. Department of Defense.

Children's Hospital Boston is home to the world's largest research enterprise based at a pediatric medical center, where its discoveries have benefited both children and adults since 1869. More than 500 scientists, including eight members of the National Academy of Sciences, 11 members of the Institute of Medicine and 12 members of the Howard Hughes Medical Institute comprise Children's research community.

Founded as a 20-bed hospital for children, Children's Hospital Boston today is a 397-bed comprehensive center for pediatric and adolescent health care grounded in the values of excellence in patient care and sensitivity to the complex needs and diversity of children and families. Children's also is the primary pediatric teaching affiliate of Harvard Medical School. For more information about the hospital and its research visit: childrenshospital.org/newsroom.

Contact: Bess Andrews elizabeth.andrews@childrens.harvard.edu 617-919-3110 Children's Hospital Boston

Tags: Nano or Nanotechnology and Nanotech