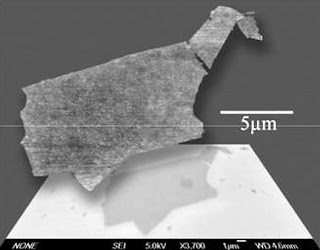

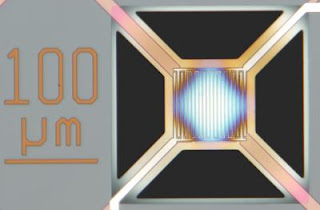

This image was taken from an animation depicting how tiny silicon "nanowires" form from gold nanoparticles exposed to a gas containing silicon. Researchers at Purdue and IBM's Thomas J. Watson Research Center used an instrument called a transmission electron microscope to watch how nanowires made of silicon "nucleate," or begin to form before growing into wires. Findings showed that the process is likely highly repeatable, meaning that the wires probably can be manufactured for future computers and electronics. (Image courtesy of Seyet LLC) | WEST LAFAYETTE, Ind. - Researchers have discovered that tiny structures called silicon nanowires might be ideal for manufacturing in future computers and consumer electronics because they form the same way every time.

The researchers use an instrument called a transmission electron microscope to watch how nanowires made of silicon "nucleate," or begin to form, before growing into wires, said Eric Stach, an assistant professor of materials engineering at Purdue University.

The work is based at IBM's Thomas J. Watson Research Center in Yorktown Heights, N.Y., and at Purdue's Birck Nanotechnology Center in the university's Discovery Park. |

The nucleation process can be likened to the beginning of ice forming in a pool of water placed in a freezer. The liquid undergoes a "phase transition," changing from the liquid to the solid phase.

"What's unusual about this work is that we are looking at these things on an extremely small scale," Stach said. "The three major findings are that you can see that the nucleation process on this small scale is highly repeatable, that you can measure and predict when it's going to occur, and that those two facts together give you a sense that you could confidently design systems to manufacture these nanowires for electronics."

It was the first time researchers had made such precise measurements of the nucleation process in nanowires, he said.

| Findings will be detailed in a research paper appearing Friday (Nov. 14) in the journal Science. The paper was written by Purdue doctoral student Bong Joong Kim and Stach and IBM materials scientists Frances Ross, Jerry Tersoff, Suneel Kodambaka and Mark Reuter from the physical sciences department at the Watson Research Center. |

Real time observations of nanowire nucleation |

The silicon nanowires begin forming from tiny gold nanoparticles ranging in size from 10 to 40 nanometers, or billionths of a meter. By comparison, a human red blood cell is more than 100 times larger than the gold particles.

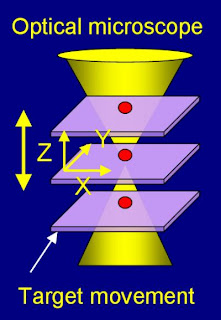

The gold particles are placed in the microscope's vacuum chamber and then exposed to a gas containing silicon, and the particles act as a catalyst to liberate silicon from the gas to form into solid wires. The particles are heated to about 600 degrees Celsius, or more than 1,100 degrees Fahrenheit, causing them to melt as they become "supersaturated" with silicon from the gas. With increasing exposure, the liquid gold eventually contains too much silicon and the silicon precipitates as a solid, causing the nanowire to begin forming.

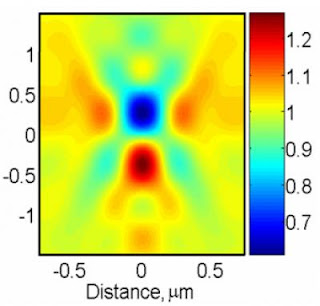

"We found that there is a single nucleation event in each little droplet and that all of the nucleation events occur in a very controllable fashion," Stach said. "The implication is that if you are trying to create electronic devices based on these technologies, you could actually predict when things are going to start their crystal growth process. You can see that it's going to happen the same way every time, and thus that there is some potential for doing things in a repeatable fashion in electronics manufacturing."

The research is funded by the National Science Foundation through the NSF's Electronic Materials Division.

Although the researchers studied silicon, the same findings could be applied to manufacturing nanowires made of other semiconducting materials. The electron microscope is the only instrument capable of observing the nanowire nucleation process, which would have to be a thousand times larger to be seen with a light microscope, Stach said.

Nanowires might enable engineers to solve a problem threatening to derail the electronics industry. New technologies will be needed for industry to keep pace with Moore's law, an unofficial rule stating that the number of transistors on a computer chip doubles about every 18 months, resulting in rapid progress in computers and telecommunications. Doubling the number of devices that can fit on a computer chip translates into a similar increase in performance. However, it is becoming increasingly difficult to continue shrinking electronic devices made of conventional silicon-based semiconductors.

"In something like five to, at most, 10 years, silicon transistor dimensions will have been scaled to their limit," Stach said.

Transistors made of nanowires represent one potential way to continue the tradition of Moore's law.

"Nanowires of silicon and things like gallium arsenide, gallium nitride or indium arsenide, or other types of exotic semiconductors, are being investigated as a step toward continuing to scale electronics down," Stach said. "If you want to manufacture devices made of nanowires, make them the same way every time on a 12-inch wafer, then you need to understand the basic physics of how to start their growth, the kinetics of their continued growth, how to quantify that, how to understand it. We are looking at all steps in nucleation."

One challenge to using nanowires in electronics will be finding materials to replace gold as a catalyst.

"Gold is not the best metal from an electronics perspective," Stach said. "We would rather use metals like copper, nickel or aluminum."

The gold particles are created inside the microscope chamber, but future research may use gold nanoparticles manufactured to more uniform standards using a different technology.

The research was conducted using an IBM microscope. The researchers also are extending the observations using a transmission electron microscope at the Birck Nanotechnology Center to look at smaller nanoparticles. ###

Writer: Emil Venere, (765) 494-4709,

venere@purdue.edu Source: Eric Stach, (765) 494-1466,

eastach@purdue.eduRelated Web site: Eric Stach:

engineering.purdue.edu/MSE/People/Abstract on the research in this release is available at:

news.uns.purdue.edu/x/2008b/NanowiresPurdue University News Service 400 Centennial Mall Drive, Rm. 324 West Lafayette, IN 47907-2016 Voice: 765-494-2096 FAX: 765-494-0401

ABSTRACT: Kinetics of Individual Nucleation Events Observed

in Nanoscale Vapor-Liquid-Solid Growth

B.J. Kim,1 J. Tersoff,2 S. Kodambaka,2* M.C. Reuter,2

E. A. Stach,1† F.M. Ross 2†

1-School of Materials Engineering and Birck Nanotechnology Center, Purdue University, West Lafayette, IN; 2-T. J. Watson Research Center, IBM, Yorktown Heights, NY; *Present address: Department of Materials Science and Engineering, University of California Los Angeles

†To whom correspondence should be addressed. E-mail:

eastach@purdue.edu (E.A.S.);

fmross@us.ibm.com (F.M.R.)

We measured the nucleation and growth kinetics of solid silicon (Si) from liquid gold-Si (AuSi) catalyst particles as the Si supersaturation increased, which is the first step of the vapor-liquid-solid growth of nanowires. Quantitative measurements agree well with a kinetic model, providing a unified picture of the growth process. Nucleation is heterogeneous, occurring consistently at the edge of the AuSi droplet, yet it is intrinsic and highly reproducible.

We studied the critical supersaturation required for nucleation and found no observable size effects, even for systems down to 12 nanometers in diameter. For applications in nanoscale technology, the reproducibility is essential, heterogeneity promises greater control of nucleation, and the absence of strong size effects simplifies process design.