| UWM research helps industry make stronger, lighter and cheaper alloys High performance metals could revive foundries. |

They sound futuristic, but these products are already realities thanks to materials that stretch the limits of performance. Called cast metal matrix composites (MMCs), they are cheaper, lighter and stronger than their original alloys. In fact, an aluminum-based MMC developed at the University of Wisconsin-Milwaukee (UWM) can replace iron-based alloys.

"These composites have many applications in the transportation, small engines, aerospace and computer industries," says Pradeep Rohatgi, a Wisconsin Distinguished Professor of Engineering who pioneered cost-effective methods of manufacturing these composites.

Now more than a 100-million-a-year industry themselves, MMCs have been used in components for train brakes, thermal management devices in computers, and even the space shuttle and the Hubble Space Telescope.

MMCs are engineered by combining metal with a totally different class of material, such as ceramics and recycled waste. Incorporating the two materials – the matrix and the reinforcement materials – result in amazing structural and physical properties not available in the natural world.

But MMCs would not have risen so far so fast without the research of Rohatgi, who currently is developing innovations such as composites embedded with nanoparticles that can deliver qualities such as self-lubrication, abrasion-resistance and energy-absorbing capabilities. He is also creating a robust "metallic syntactic foam."

"One thing that has surprised me over the years is how easy it was to make these materials," he says.

It was Rohatgi's adaptation of a conventional foundry process to synthesize aluminum and graphite that slashed the cost of mass-producing MMCs and allowed for more complex shapes to be made.

Since then, his laboratory has done extensive work in reinforcing aluminum with elements such as graphite and silicon carbide particles (ceramics) to form materials that are 20 to 40 percent stronger. The aluminum embedded with graphite also self-lubricates, making it particularly valuable for use in engines.

Standard aluminum pistons and cylinders can stick together during a cold-engine startup or when an engine needs oil, he says. But if the parts are made from an aluminum-graphite composite, the engine is partially protected from seizing.

This year, his lab received a half million dollars in federal money to develop lighter, heavy-duty materials to meet the U.S. Army's need for vehicles that can be airlifted and operate for prolonged periods without refueling.

For all the work he has done with major car companies and Wisconsin partners like Oshkosh Truck Corp., Rohatgi says the largest users of MMCs have not been in transportation, but in the computer industry.

Computer applications require smaller volumes and they often have the money to invest in new technologies, he says. "You look for the big bang in one area and it happens in another."

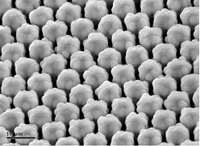

The newest class of MMCs that his lab is developing fortifies aluminum with nanoparticles to produce materials that can withstand enormous amounts of stress, are exceptionally hard, but are also lightweight. Nanoparticles are smaller than 100 nanometers (about the size of a baseball shrunk to one-millionth of its original size) that sometimes behave differently than larger particles.

A nanostructured aluminum can be 10 times stronger than conventional aluminum alloys.

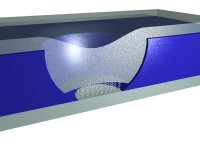

A third kind of MMC Rohatgi is working on turns metals into foam.

Unlike Styrofoam, in which air is pumped into a plastic matrix, syntactic (metallic) foam is filled with hollow micro-balloons set into a metal base. The tiny balloons are made from recycled "fly-ash"-- waste materials generated by coal-burning power plants – and they house either various gases or are a vacuum inside.

"The cells are smaller and more regular than air bubbles, which make them better at energy absorption, in the case of a car crash, and also useful at sound dampening," he says. "They are also very light and there may be an interest in aluminum foam in homeland security issues. It can make buildings, including bomb shelters, more blast-proof and fire-resistant."

Now in his 20th year at UWM, Rohatgi continues to help foundries, such Eck Industries in Manitowoc, diversify their business with MMC casting, giving them a defense against competition from other countries where labor is cheaper.

His lab is researching techniques that will enable industries to manufacture composite components with increased speed – and the new technology will taking the process out of the factory, making on-site manufacture of parts possible.

The U.S. military also is interested in developing the capability of quickly producing replacement parts for vehicles while on the battlefield. Rapid manufacturing technologies can be expanded to include lightweight materials for bone replacement implants and tissue scaffolds, says Rohatgi, improving the treatment of wounded soldiers in mobile environments.

"The only way to keep foundries viable is to help them develop fast-track technologies to manufacture components from advanced lightweight materials," Rohatgi says. "It gives old-line manufacturing the means to producing high-tech products."

### Contact: Pradeep Rohatgi prohatgi@uwm.edu 414-229-4987 University of Wisconsin - Milwaukee

Technorati Tags: nanofibers or Nanoscientists and Nano or Nanotechnology and nanoparticles or Nanotech and nanotubes or nanochemistry and nanoscale or nanowires and Nanocantilevers or nanometrology and nanostructure or metal matrix composites and University of Wisconsin-Milwaukee or Pradeep Rohatgi